RECENT PROJECTS

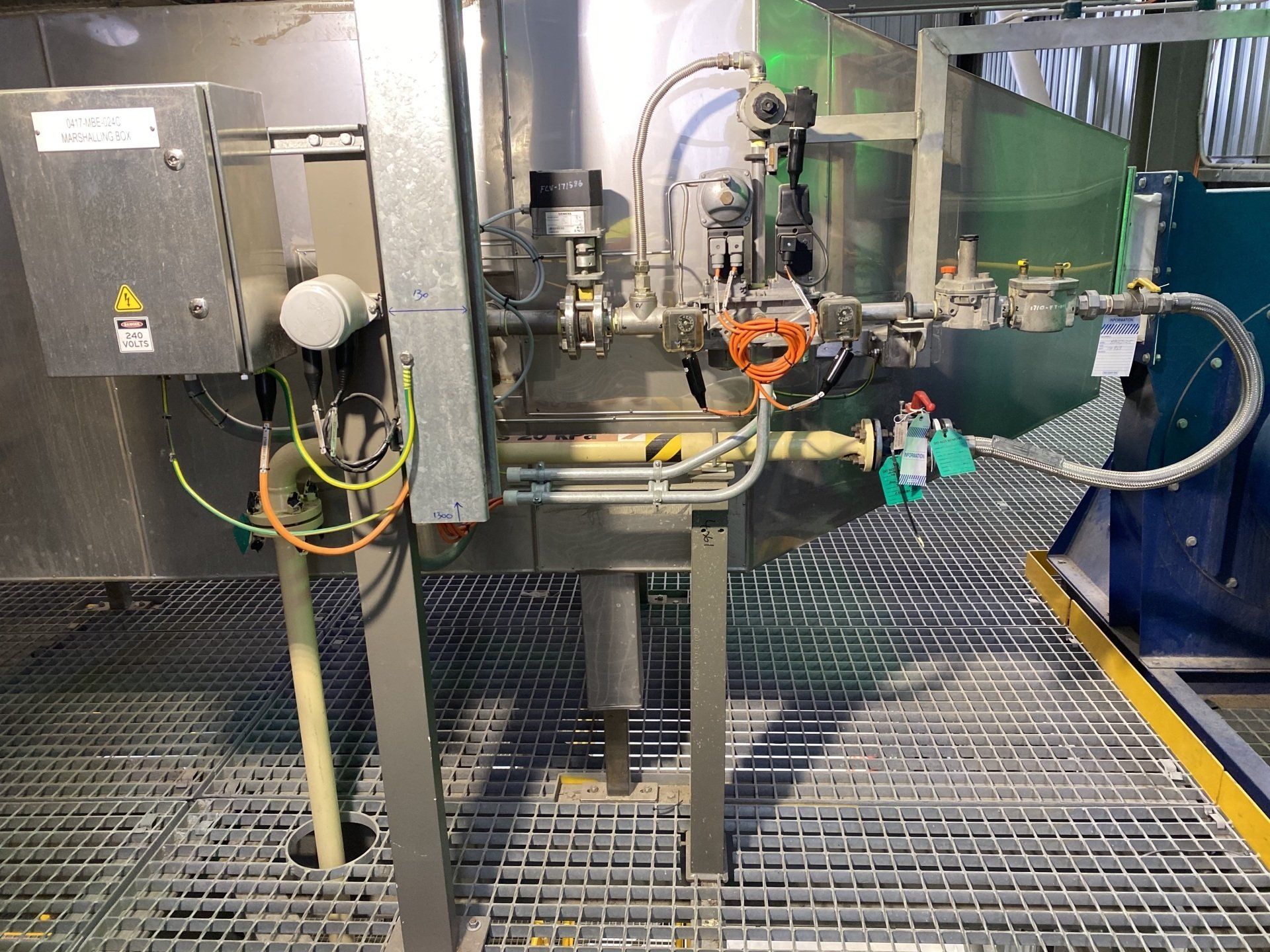

10 GJ Blast Furnace air pre-heater

Successful commissioning of a new 10 GJ in duct burner system to pre-heat combustion air for a lead smelting blast furnace based in Port Pirie, South Australia.

The direct fired air preheater uses a natural gas burner to fire directly in to a process air stream, preheating the air to approx 150C. This system improves the energy efficiency of the blast furnace.

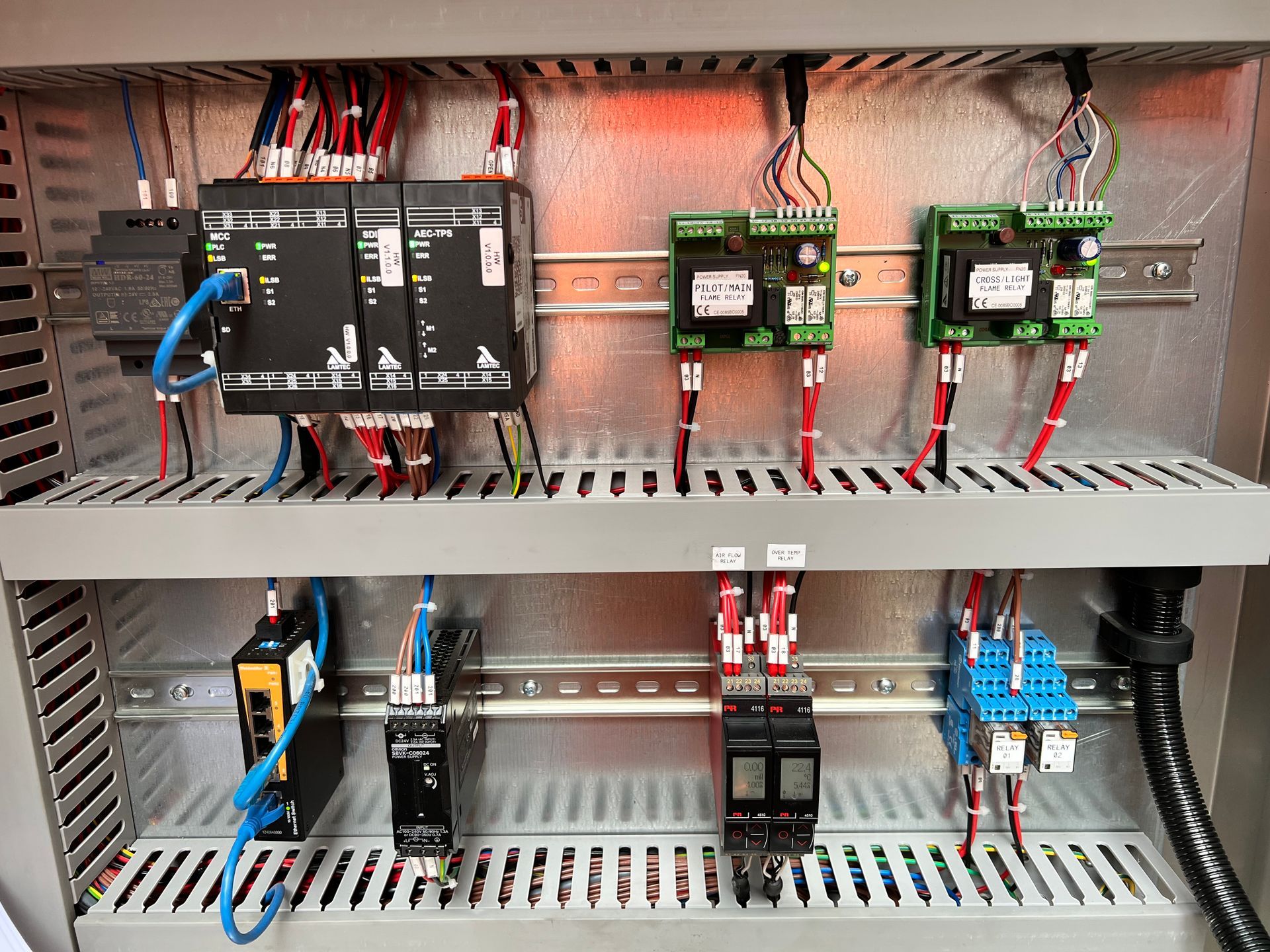

5GJ Fluid Bed Drier

Installation and commissioning of newly supplied fluid bed drier for a client in the Pilbra.

Drier was supplied with a Burner Management System (BMS) that does not conform to Australian Standards.

Removed currently installed BMS and supplied, installed, programmed and commissioned new BMS system comprising of a LAMTEC® CMS Modular, micro-processor-based burner management system and installed additional over temperature protection BMS interlocks and air flow proving circuits for compliance with AS/NZS 3814.